TOOLING

The process

DESIGN

TOOLING

CASTING

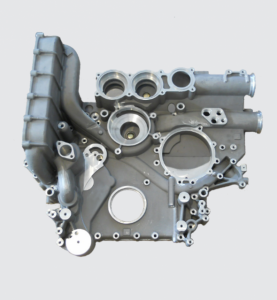

Particular mathematical modeling: from drawing, in co-design. Design and processing of customer's mathematical models for feasibility study according to foundry criteria and requirement

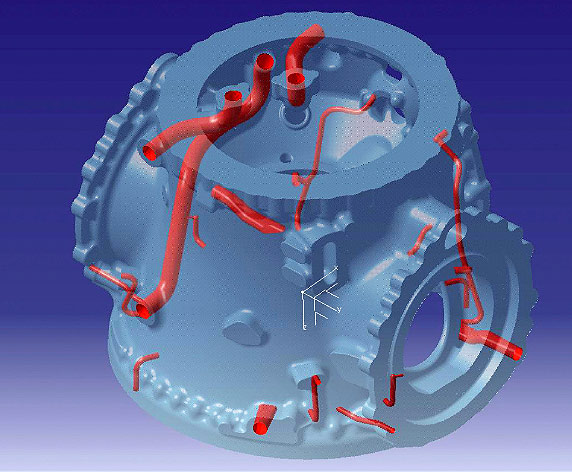

Study and design assembly of cores/patterns/moulding boxes

Design of casting and supply systems with software simulation testing

Design and processing of Client's mathematical models for feasability study according to foundry criteria and requirement

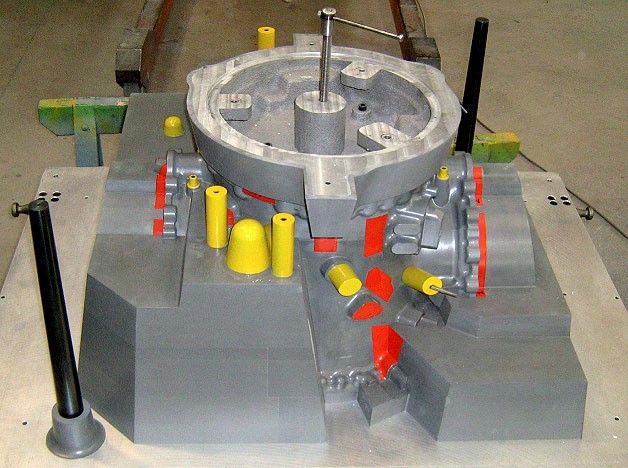

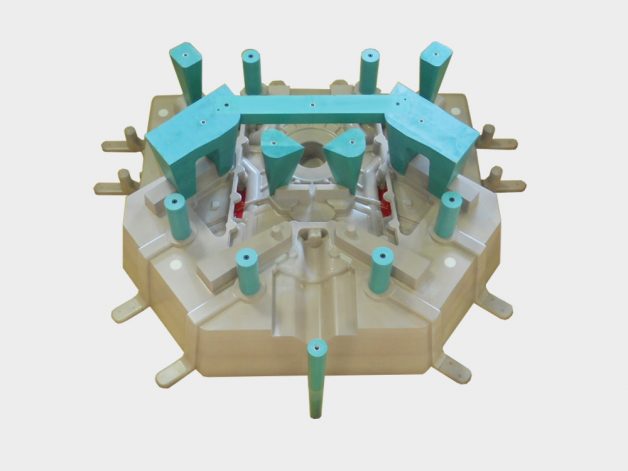

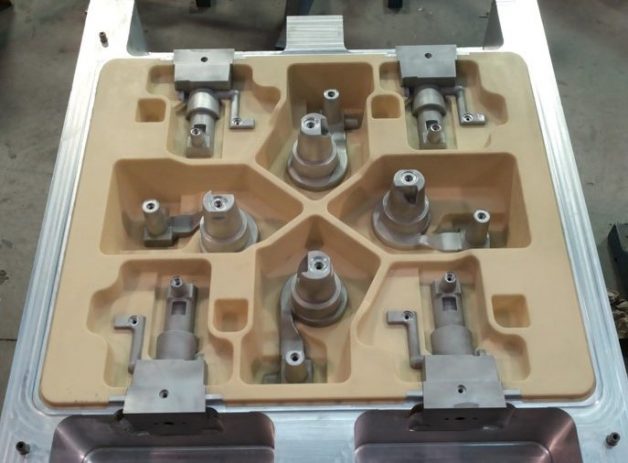

For mass production, we use aluminum or steel with special resin blends that allow the manufacture of high-capacity equipment with excellent geometry guarantees combined with high wear resistance

Example of production core box with trolleys mounted on bearing guides

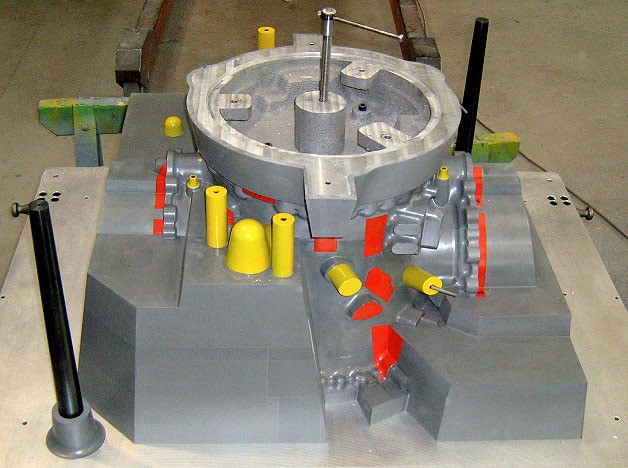

Finishing operation of a model. All equipment undergoes dimensional inspection and is accompanied by a certificate of conformity

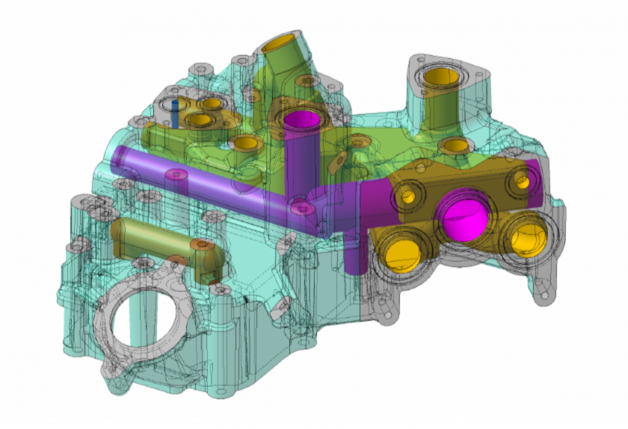

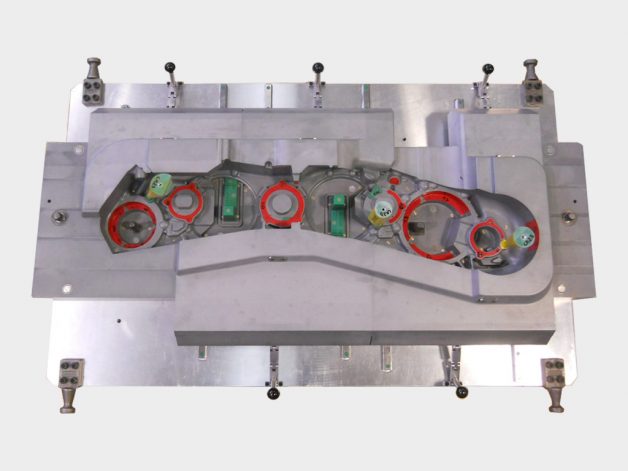

Design and construction of mold assembly gauges, leak test tools, casting calibration tools, casting processing tools

All toolings are subjected to dimensional inspection and accompanied by certificate of conformity